Built-in wardrobe according to your own design and with your own hands. DIY built-in wardrobe: step-by-step instructions DIY built-in wardrobe in the wall

As you know, in the modern market there are many furniture manufacturing companies that offer a wide range of products, for example, popular and necessary wardrobes. On the one hand, you can purchase this option in any store, entrusting its assembly to experienced craftsmen. On the other hand, an item made independently is much more valuable and proud for the owner.

Let the maximum amount of time and effort be spent on this, but one cannot but agree that a hand-made wardrobe will ideally meet the household needs of the owner of the house.

Deciding on the type

If you are designing the installation of a cabinet in the hallway, it is important to take into account that in many apartments it is small and rectangular in shape. Unlike the hinged doors of a conventional wardrobe, sliding compartment doors will ensure space saving in the best possible way.

Maintaining free space is important in any room, not only in the hallway, but also in the bedroom, which should always remain an area of comfortable relaxation and order. If the height is made up to the ceiling, the usually empty space will be used with maximum benefit.

In the corner area of a living space, depending on the characteristics of its total area, an unusual and spacious radius wardrobe can be placed. Corner placement is advantageous in that a piece of furniture installed in this way will accommodate much more things than with another option.

However, it is quite difficult to manufacture, so it is better for a novice master not to tackle it, but to limit himself to a simple rectangular model.

A built-in wardrobe can be installed if there is a niche or pantry in the room. It will be functional, convenient and aesthetically pleasing. In addition, making a closet from a pantry yourself is much easier than making it completely: it already has walls, a ceiling and interior space. The main task is to decide on the contents of such a cabinet, to correctly plan the dimensions, drawing and course of action.

Materials

You should choose materials carefully, first of all thinking about strength, reliability and durability.

Tree

If we are talking about wood, then it is not suitable for creating a built-in wardrobe, because in a niche or closet the humidity level is much higher than in the room. Any tree will quickly begin to crack and lose its natural beauty. As a last resort, you can use it to create small components and decorative elements, but with mandatory pre-treatment with a water-polymer emulsion or drying oil.

Drywall

Recently, drywall has been a very popular material. However, professional furniture assemblers do not recommend its use. This material is characterized by increased fragility and is very heavy in weight.

In addition, it must be attached to some solid base.

Shelves made of plasterboard quickly begin to “sag” under the weight of things, crack and deform. You can use it to create other pieces of furniture, but it is absolutely not suitable for making a high-quality wardrobe.

Fiberboard, MDF and chipboard

The best options are fiberboard, MDF or laminated chipboard. It is these materials that have always been distinguished by their strength and reliability, they are easy and simple to work with, and humidity and temperature changes do not affect them. A large selection in markets and stores of various color shades of laminated chipboard will allow anyone to choose the desired color.

An important point: for the purpose of making cabinets, there is a certain standard of laminated chipboard sheets with a thickness of 16 mm.

Plywood

Plywood is no less versatile and durable. It can also be laminated; you can find varieties of it on sale that are water-resistant and insensitive to high humidity, which is important when placing a wardrobe in a niche or closet.

Plywood combines both strength and flexibility when processed because it is made from soft wood species. It should be remembered that when screwing self-tapping screws into it, it may become deformed, but this will not happen if you use washer-shaped gaskets.

Furniture panels

A sliding wardrobe can also be made from furniture panels. First of all, they are famous for their visual appeal and low price. This material is based on natural wood species such as oak, alder, and birch. When creating furniture, panels are usually combined with plywood in the following way: the frame and facade of the structure are made from them, and shelves and drawers are made from plywood.

The standard thickness is 2 cm.

From an old cabinet that has served its purpose, you can make elements that may be needed when creating a new one. Sometimes chipboard sheets from old furniture are extremely durable: unlike many modern materials, it is impossible to even screw screws into them without first creating a special hole. In this case, old but strong chipboard panels will ideally fit inside the cabinet as durable shelves.

If the appropriate material has already been selected, all that remains is to purchase ready-made sliding doors for the future wardrobe. Of course, you can make them yourself, but it will cost much more than purchasing doors that are ready for installation. You should find a good company that manufactures sliding doors and place an order there, indicating the dimensions of the opening and the number of panels.

In order for sliding doors to serve as long as possible, you must purchase a self-adhesive seal. Its main purpose is not only fastening profiles in grooves. If the seal is of good quality, it will prevent dust from entering, and the cabinet doors will move absolutely silently.

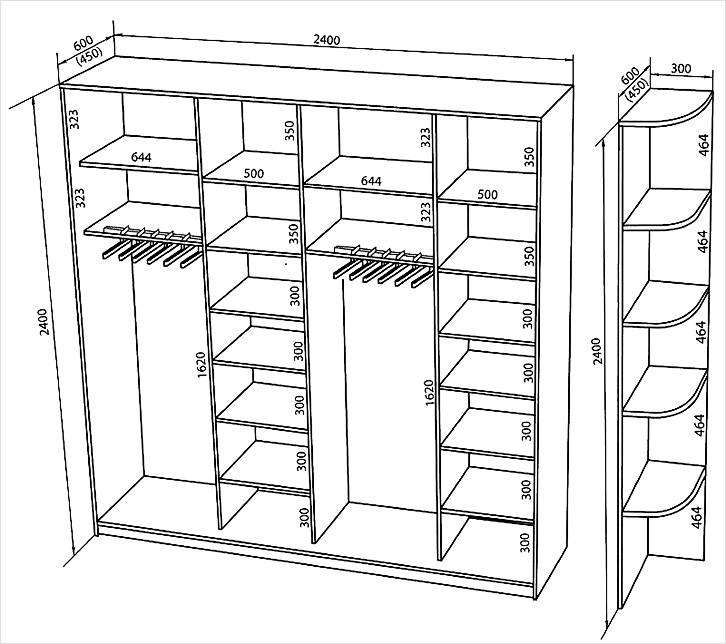

Description of drawings

Before starting to assemble any piece of furniture, it is necessary to create a certain diagram in the form of a drawing. The dimensions should be carefully verified, with the obligatory indication of all parameters both on the outside and inside the structure, while being sure to indicate the thickness of each partition.

When drawing up a drawing, it is important to comply with certain size standards in advance: for example, it is recommended to leave the optimal distance between shelves at 30-40 cm, and the depth of the drawer should be no more than 50-55 cm.

Before creating a drawing, you need to decide on the main characteristics that the future wardrobe will have:

- height, width and depth;

- height of mezzanines, if planned;

- how many doors, drawers and other sections there will be in the closet;

- what content is planned: drawers, crossbars, shelves, etc.

After this, a sketch of the future cabinet is drawn. If you have experience and the ability to draw, you can make a drawing yourself, simply using a sheet of paper. There is also a simple solution for those who are not good at drawing: special computer programs into which you just need to enter certain data, and the computer will produce a ready-made, full-fledged drawing. The quality and accuracy of such a drawing is so high that with its help you can safely begin to assemble the cabinet yourself.

Step-by-step instruction

Room measurements and calculations

First, using a tape measure, determine the three horizontal dimensions of the niche from the outside: top, middle and bottom. Then the same three measurements are taken along the back wall. This is necessary in order to understand what size future shelves will have to be cut out. Next, similar dimensions (front and along the back wall of the niche) are taken vertically in height: left edge, middle and right edge.

This helps to understand what the overall size picture will be.

It is important to remember that measurement error is quite common. It is determined by the quality of the construction of the house and the alignment of the walls. Dimensions with all errors should be recorded in the drawing in order to make calculations as accurately as possible.

At this stage, you need to finally decide on the cabinet detailing. What will be located and where, how many sliding facades are planned to be installed, how many departments are there in total, will there be open corner shelves in the closet, will there be a need for an illuminated canopy.

Since we are talking about a small closet, which is located in the hallway, you can immediately decide what to put where. Outdoor shoes can simply be placed on the floor in a niche, without the use of shelves made of chipboard or other material. It is also advisable to think through the internal filling of the closet in advance: the number of compartments for clothes, drawers, shelves, hanging rods.

All measurements must be carried out taking into account the thickness of all materials used.

It is important not to forget to carefully mark the dimensions between the shelves. If the niche is crooked, then the shelves will need to be made with an allowance to accurately fit the dimensions of the walls. The dimensions of each part should be described, taking into account the plastic edge (PVC, usually 2 mm).

It’s good if the installation happens quickly, without unnecessary adjustments.

Cutting and fittings

If you really want, you can cut out the parts yourself, but this is not necessary. It is better to send the finished drawing to the production workshop, where all components for the cabinet will be manufactured exactly according to the specified dimensions. Therefore, the drawing must be drawn up as accurately and correctly as possible, and at a proven, reliable furniture factory, all the necessary elements for the upcoming assembly will be qualitatively cut from it.

As for fittings, there will be no problems purchasing them now either: they are presented in a large assortment in large construction or specialized stores. Here is an approximate list of what may be needed when making a simple built-in cabinet:

- dowels and self-tapping screws,

- gaskets for soft installation of self-tapping screws,

- furniture corners (preferably metal),

- a hanger rod with rod holders (if the closet is small, one will be enough),

- hooks, clips for attaching shoe shelves.

Construction assembly and installation

Since this is not a cabinet cabinet, but a built-in cabinet, the top and side panels of which replace the walls, you can start right away by determining the location for the shelves. Several marks are made on the wall with a pencil, and the shelves themselves are fastened using mounting angles.

It is better if they are metal rather than plastic: the former are durable and look very aesthetically pleasing. The corners are attached using dowels and self-tapping screws.

If the closet has shelves whose length exceeds 800 mm, they need additional fastening, otherwise over time any material may bend under the weight of things. Therefore, the shelves along the back wall should be reinforced with metal corners.

The hanging rod is attached to the wall using special round rod holders. Each of them has three holes, and fastening to the wall is carried out with pegs and self-tapping screws.

At the bottom you can install a mesh type shoe rack. It is attached using special hooks or clips, and is installed at the desired level after first marking its location with a pencil.

Then you need to secure the shelf along the front side walls with metal corners.

If the room has a suspended ceiling, in order to correctly combine such a ceiling and a wardrobe, you will need to place a mortgage between them in the form of a beam up to 100 mm wide.

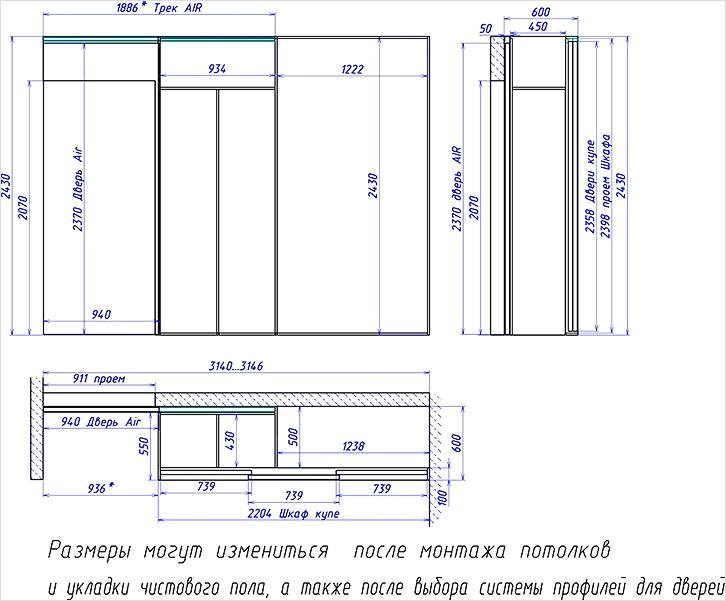

Installation of doors with guides

As already noted, the ceiling is not always smooth and ideal. Therefore, the primary task when installing the top guide for sliding doors is its alignment and installation clearly horizontally. To do this, you will need to lay linings of varying thicknesses between the guide and the ceiling.

You can make them from MDF. The resulting gap in the conclusion is closed with a frieze made of 8 mm thick chipboard.

Now you need to measure the height of the niche on the left and right in order to calculate the possible slope of the floor or ceiling, as well as the collapse of the walls. Having established the difference in size, you need to take the MDF spacers again and place them between the guide and the ceiling. Only now, after all the installed gaskets, can the upper guide be finally secured. Drill a hole in the ceiling, hammer in a dowel, then the guide is finally attached to the ceiling with self-tapping screws.

When trying on a frieze, it is important to make allowances in order to adjust all the parts to size during installation. Place the frieze on the gap, mark the required lines with a pencil and cut along them. You can glue the frieze to the guide using double-sided tape. In order for the tape to adhere well, it is necessary to first degrease the surface to be glued with alcohol. Then stick vertical strips of tape on the surface, remove the protective film from it and glue the frieze to the top guide.

The bottom guide for the cabinet doors is also attached with double-sided tape. This will ensure its smooth and soft movement - the doors will move silently, with minimal wear on the rollers. The doors themselves need to be inserted into ready-to-use upper and lower guides and adjusted.

Detailed instructions for assembling and installing sliding doors can be viewed in the following video.

In order not to be limited by standard rectangular shapes when creating a cabinet, you can use creative ingenuity in working with such a soft and pliable material as plywood. You can create a smooth and unusual shape of a shelf or other element of a piece of furniture by moistening a sheet of plywood with water and placing it on a special form - a blank. Within 12-14 hours, the sheet will acquire the desired smooth outline and will be ready for use.

In addition, there is the simplest and most uncomplicated way of attaching shelves to a cabinet using pieces of the most ordinary baseboard. MDF plinths are characterized by increased strength, sometimes not inferior in reliability to metal fittings. To ensure that such fastening of the shelf is not too conspicuous, a piece of plinth can be made one third shorter than the depth of the shelf, and its end can be cut off at an angle.

In this case, the self-tapping screw farthest from the edge of the shelf will have to be screwed in from above, through the shelf board.

The use of stained glass technology for decoration

The door panels of the wardrobe can be decorated using stained glass. The cost of manufacturing such facade decorations varies; it directly depends on the degree of complexity of the technology used. In any case, inexpensive options for stained glass cabinet design will look great, but only if they are made of high quality.

There are three main types of stained glass that are most often used for decoration:

- Classic stained glass. It will look best framed in a wooden or metal frame. Glass can have any pattern or different colors. The manufacturing process of such stained glass is very labor intensive, which gives it both prestige and a fairly high price.

- Tiffany. Its difference from classic stained glass is that it is possible to use this option if there is no frame on the facade. In this case, the drawing turns out to be more intricate and original. Technically it is no less complex than the classic, but aesthetically very beautiful. Even its obvious fragility may not be considered a serious drawback compared to its beauty.

- Filled type of stained glass. It is also called contour. One of the popular imitations of expensive Tiffany, performed on a large glass canvas. This stained glass window, due to its simpler manufacturing technique and low price, is the most popular among consumers. It is resistant to external damage and very practical, which allows it to be successfully used when decorating the simplest furniture options.

Sandblasting patterns on mirrors

If the facade of the wardrobe is made in the form of a mirror coating or glass, you can apply a beautiful sandblasted pattern to it. This is an abrasive type of surface treatment using sand sprayed using a special apparatus under a certain air pressure.

This technology provides any furniture with unique and realistic designs that have volume and texture. Once upon a time, when there were no sandblasting machines yet, in the ancient Roman Empire similar glass processing was done manually using a flat stone: they rubbed sea sand over the surface of the glass.

Sandblasted images have a porous structure and, unfortunately, can easily get dirty. This is its only drawback, which can be overcome by protecting the surface of the drawing with varnish or a special solution that contains polymer components.

Vinyl stickers

An excellent and easiest way to decorate the facade of a wardrobe if you cannot afford to order stained glass or sandblasting. Typically, such stickers look like transparent photo wallpaper. A special film is used in their production. Thanks to its transparency and monochromatic design, you can easily match the sticker to the color of any cabinet.

You can replace an old, boring sticker with a new one at any time - it can be easily removed without leaving marks on the mirror or glass.

Furnishing the home is the final step that combines all renovation and design stages. Modern furniture should combine several important qualities: operational functionality, appearance as such, and compliance with the overall design idea.

Coupe systems or their elements are present in almost every home. The convenience and functionality of this furniture is undeniable, and for such design styles as minimalism, urban, hi-tech, it is completely irreplaceable. The article provides comprehensive recommendations for making your own wardrobe.

Advantages

Having considered the pros and cons of this class of furniture, we will get a complete understanding of the modern concept of a wardrobe with a compartment door opening system.

| Advantages | |

| Ergonomics | Standard designs require “blind” areas for opening. In coupe systems, doors move in one plane along guides when opening and closing. Significantly saved space. |

| Capacity | The ability to arbitrarily configure the internal space (filling), which determines the capacity. The only requirement is ergonomic feasibility. |

| Versatility | Fits into any interior. Various design and finishing methods allow you to install the cabinet in the bedroom, kitchen, living room, etc. |

| Functionality | Inside, unlike ordinary cabinets, you can store large items and household appliances. Build in various devices - ironing board, workbench, tabletop, etc. |

| Ideal solution for narrow spaces | For narrow aisles and corridors, a sliding wardrobe is often the only solution. Only it can be placed in such places and used comfortably. |

| Zoning | Dual functionality. Using such furniture, you can easily zone a room, that is, it can also serve as a partition. |

| Variety of designs | No restrictions on internal content. A large number of materials for the manufacture of facades, which allows you to realize any design idea. |

| Using a mirror | You can install a mirror on the facade. This will improve the functionality of the room and visually expand the space. |

| Reliability during operation | Doors that move along guides will last much longer than doors that open on hinges. |

There are significantly fewer disadvantages, but they are there:

| Flaws | |

| Failure of the sliding system | This only happens if you purchase a low-quality sliding system. |

| Need for additional lighting | If the dimensions are large, additional lighting will be required; it significantly increases operational comfort. |

| The need to clean the guides | Over time, the lower guides become clogged, which can interfere with the movement of the roller. Therefore, sometimes you have to clean the grooves of the guides. |

| The mirror gets dirty quickly | If a mirror is used in the decoration, then it will have to be washed frequently to remove stains and hand marks. |

| No possibility of rearrangement | When designing, dimensions are related to the specific location of the cabinet. Not suitable for those who like frequent rearrangements. |

Varieties by shape

There are several varieties, they have structural and external differences:

- built-in;

- free-standing;

- corner;

- diagonal-angular.

Let's consider each of them separately.

Built-in

When constructing such a cabinet, there is no top, back wall and base. Only partitions are manufactured. The entire structure is screwed directly to the ceiling, walls and floor. Metal corners are used for fixation.

This is a stationary structure, and it is an invariable part of the created interior.

Standing separately

Has sides, top, bottom, back and sliding doors. This is a complete separate piece of furniture. It can be moved and is not tied to any design elements.

Angular

An excellent solution for small apartments where every meter is valuable. Repeats the shape of the corner and allows you to rationally use the space of the room.

Diagonal corner

This is a type of corner, but the facade does not follow the shape of the corner, but is made diagonal. The increased capacity of this design determines its frequent use as a dressing room.

Material used

Furniture with sliding door systems is made from a variety of materials. The table shows the main ones:

|

Material |

|

|

|

The most common and frequently used. Chipboard, having a low price, is quite durable. A huge selection of textures, colors, patterns allows you to produce a façade for any design solutions. There is one, but significant, drawback - it is difficult to finely process. For this reason, mostly simple structures are made from chipboard or laminated chipboard. |

|

|

Eco-friendly material, easy to process. The variety of facade coatings is no less than that of chipboard. Practical and affordable material. |

|

|

An expensive option, but natural wood will last a long time. A magnificent decoration in any interior. |

Types by design

The classification according to design differences is as follows:

- built-in;

- case.

Built-in . There is no need for top, bottom or sides. Their function is performed by the walls, floor and ceiling of the niche. For manufacturing, you can use drywall, which will reduce the overall cost of the product.

Corpus . The main difference from a regular cabinet is the method of opening the doors. If necessary, you can move it. Transportation (moving) without disassembly is possible. The downside is the increased consumption of materials, since the side, bottom and top walls, and the rear part are made.

Now let's take a closer look at the organization of the internal volume of the cabinet.

Design features

When designing, ergonomic and operational specifics should be taken into account.

Let's look at the main structural elements of a sliding wardrobe.

Door width

The choice of door size depends on factors:

- Manufacturers of sliding systems are limited to certain sizes. Some systems make it possible to produce a sash up to 120 cm wide;

- The width is affected by the number of internal sections. Each section must be freely accessible;

- The choice is influenced by personal preferences. There are no special rules, unless it goes beyond the restrictions listed above.

The optimal width, worked out in practice, is from 600 to 900 mm. This size provides the most comfortable conditions of use.

Sliding systems

Sliding systems are classified according to two main criteria:

- profile material;

- principle of extension.

To manufacture the profile of the moving system, aluminum or steel is used. The material of the sliding system is selected, as a rule, the same as that used for the door frame. Steel structures are cheaper, but in most cases aluminum is preferred.

Structurally, two types of systems are produced - bottom-mounted and top-hung. In the lower-support type, the door with rollers moves along a rail. In the top-hung system, its rollers move along the upper guides.

Height

The height is arbitrary. The only limitation may be the ceilings or the small stature of the owners of the apartment/house. Structures are made from ceiling to floor, as well as smaller heights.

The standard length of the material used for the walls is 270 cm. A standard apartment has a ceiling height of 260–270 cm. Almost identical dimensions make it possible not to cut or extend structural elements.

For ceilings higher than 270 mm (if you want to have a floor-to-ceiling closet) there are two solutions. First, the sheets of material are joined to the required length. Secondly, the mezzanine is assembled. Sheets can be joined using high-precision equipment from companies specializing in such services.

Shelf depth

The depth of the shelves determines the everyday usability of the cabinet. The optimal and recommended figure is 60–70 cm. Usually in the closet there is a rod for hangers, the width of which is about 48 cm. A depth of 60 cm will completely eliminate contact between the inner surface of the door and clothes hung on hangers. Most furniture accessories (boxes, trays, etc.) have a width of 50 cm. The shelves should not be made deeper, since it will be inconvenient to get “under the wall” when placing things.

The dimensions of the premises do not always allow the installation of furniture with the maximum recommended shelf depth. But there are also restrictions on the minimum depth. The optimal option may be a depth of 40 cm. Considering that 10 cm goes under the sliding door mechanism, you can purchase small hangers 30 cm wide. Alternatively, install a hanging rod(s) perpendicular to the doors and the rear wall, in this case, the width of the hangers placed not limited.

This solution is much better than completely abandoning the installation of a cabinet, especially since even such a “narrow” design is an ideal solution for small apartments.

Length

When designing, the length of the cabinet is selected in accordance with the location of its further installation.

Height of shelves and rods

The height between shelves is 250–350 mm. The selection rule is simple: greater depth of shelves means greater distance between them, less depth means less distance. This dependence is associated with ease of access to stacks of linen located deep in the shelf (near the back wall).

When designing a mezzanine, you should take into account the size of the things intended to be stored on it. If these are suitcases, then the height of the mezzanine should be equal to the height of the suitcase, plus a small margin.

The mounting height of the hanger bar is determined by the length of the clothing placed on it. The maximum height will be equal to the longest item. Average length of typical wardrobe items:

- shirts - up to 100 cm;

- jackets - up to 110 cm;

- long clothes - up to 130 cm;

- raincoats and fur coats - up to 150 cm.

These calculations are approximate, since the length of clothing depends on height, style and other parameters.

Video:

Schemes and drawings

The diagrams show various project options and furniture assembly technologies:

Device inside

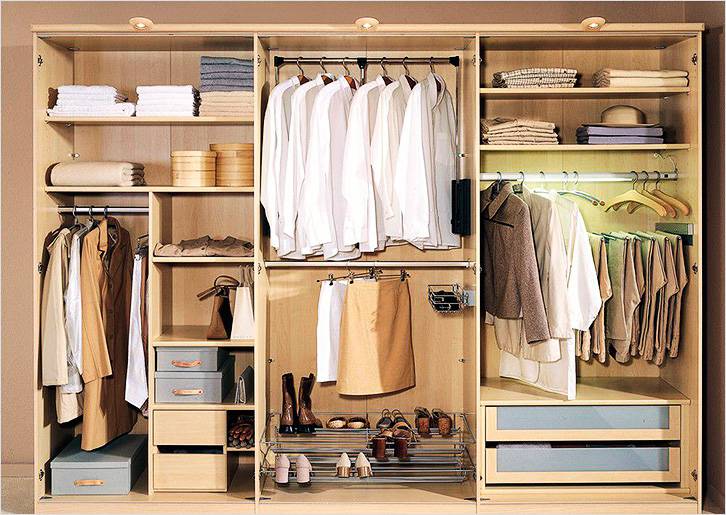

When designing the filling of a sliding wardrobe, first of all, zoning of the internal space is done. The figure shows a universal diagram of the breakdown into storage areas for various things:

When purchasing a finished product, you will have to agree with the filling configuration proposed by the manufacturer. Self-production will allow you to take into account as much as possible the dimensions, functionality, location of various zones and much more, which, ultimately, will ensure maximum operational comfort.

Below is a table with examples of frequently used elements of internal filling and zoning of a sliding wardrobe with their help.

| Zoning | |

|

|

Shelves are one of the main filling elements. They can be stationary and retractable, solid and ventilated, half and full depth, etc. |

|

|

Drawers are the second most important element of the cabinet. |

|

|

Hanging rod - necessary for clothes on hangers. The material used varies, most often metal. |

|

|

Convenient storage baskets. All things are clearly visible in them, which creates a certain convenience. |

|

|

This device is called a trouser. Pants are always ironed and ready to wear. |

|

|

A bar (hanger) for storing ties is convenient to choose, does not wrinkle, and proper suspension prevents them from changing shape. |

|

|

Convenient placement of belts, as an alternative - storage on a shelf in rolls. |

|

|

Compact and convenient storage of underwear. |

|

|

Placing bed linen, towels, and some clothes in piles on shelves. |

|

|

A significant part of the internal volume is allocated for storing blouses, light blazers, and short sundresses. A pipe with hangers is installed in the opening. You can make several such sections - for short and long things. |

|

|

Department for accessories - bracelets, watches, glasses, etc. It is recommended to store these items in drawers. Inside, the space can be divided into separate cells. |

|

|

Shelves for storing shoes. In the upper (mezzanine) part you can place shoes in boxes. |

|

|

Hooks, hangers, carabiners, rings and other accessories for bags. |

| Travel suitcases | Place rarely used (once a year during vacation) suitcases on the far (top) shelves or mezzanine. |

|

|

One of the options for bed linen. Shelf width up to 80 cm, height up to 60 cm. |

Characteristics of the main filling elements:

- retractable and stationary shelves. For convenient use, the distance between them is from 350 to 450 mm;

- drawers. Two types - fully retractable (100%), partially retractable (80%). They can be equipped with closers that provide smooth semi-automatic closing of the drawer;

- mezzanines, known as hard-to-reach shelves. Located at the top. Rarely used and bulky items are stored on them;

- Barbells are needed for hangers. Mounted along the width of the cabinet;

- pantographs or special “furniture elevators”. Thanks to them, clothes are stored at the required level and can be easily pulled out using a special rod. They can be electrical or mechanical;

- Baskets are convenient for storing small items. Equipped with rollers and guides.

Facades

The interior content, thought out to the smallest detail, will be in sharp dissonance with poorly chosen facades. It is the facades that give the entire cabinet a special finished look. Let's consider several options for their implementation.

Mirror

A mirror visually enlarges the space and makes the room brighter. Can be whole or divided into several parts. The large weight of the mirror determines the need to select high-quality and reliable rollers. Such a facade creates additional maintenance troubles - the mirror quickly gets dirty. It will have to be wiped and washed regularly, especially if the family has small children.

A variety of finishes are used for facade mirrors - sandblasting patterns and designs, spraying of various shades (silver, emerald, gold, etc.) for glass, printing color images and much more. For safety reasons, the inside of the mirror is covered with shockproof (armor) film. If the mirror breaks, the pieces will not fly away.

Glass

Glass is no less popular than mirror; facades are equipped with unbreakable ones. Frosted glass with a pattern is mainly used. Vertical and horizontal stripes that divide the canvas into separate squares look original.

MDF and chipboard

These materials are laminated with film. The facades look massive and heavy. To install them you will need reliable roller systems. One of the advantages is a huge selection of colors, shades and patterns, texture - from matte to bright glossy.

Photo printing can be applied to MDF and chipboard facades.

These are the main types of facades used in the manufacture of sliding wardrobes. You can combine them with each other. This article contains photographs with a considerable number of original ideas for making facades.

Step-by-step manufacturing instructions

Gluing the edge tape

After cutting all the elements, the edge tape is glued to the ends of the slab. Sequence of operations performed:

| Instructions for gluing the edge to the end of the workpieces | |

|

|

If you don’t have an assistant, you can use a simple trick. You will need a small box and a quick-release clamp. The clamp presses the board to the box, ensuring the stability of the workpiece and the convenience of gluing the edge tape. |

|

|

One side of the edge tape has an adhesive surface. By heating it to a high temperature it is easy to glue it to the workpiece. |

|

|

Cut the edge to the required length. Leave a margin of 1 cm at the edges. After gluing, you can cut it with ordinary scissors. |

|

|

For gluing, set the position of the iron temperature sensor to “2”. |

|

|

For safety reasons, wear two gloves on your left hand. There should be no pellets on the palm. |

|

|

Use the iron to move along the edge tape, and hold it with your left hand (flat). |

|

|

We move the iron in the opposite direction, at the same time using a gloved hand we firmly press (smooth) the edge tape. |

|

|

Use your hand to smooth the edge a few more times. |

|

|

Using a special roller. Iron on the edge tape and then roll it with a roller. Very comfortably. |

|

|

Once the tape has cooled down, carefully cut off the remainder from the end with a sharp knife. |

|

|

We get a cut like this. |

|

|

We repeat the procedure for all ends of the workpiece. We measure the tape with a margin of 1 centimeter, from each edge. |

|

|

Glue it with an iron and smooth it out. |

|

|

Cut off the cooled edge. The edge on the adjacent edge has already been glued; we make the cut very carefully. |

|

|

We cut off the longitudinal remains of the protruding edge on all sides. |

|

|

Result. We glue the edges of the remaining blanks with edge tape. |

|

|

All cuts are sanded with a special whetstone. The inside of it is filled with foam rubber, the outside is filled with fine-grained abrasive. |

|

|

Grinding of cuts is done only with longitudinal movements. |

The processing of the main elements is carried out similarly.

Assembly

According to the project, the details are cut out. It is better to do this operation in a workshop on a special formatting machine. After cutting and gluing the edges, we assemble the cabinet:

| Frame assembly instructions | |

|

|

To work, you will need to assemble an additional device consisting of a metal strip and two pieces of board connected at an angle. It turns out a corner with a metal guide. You will also need two quick-release clamps. Using this device it is very convenient to connect workpieces at right angles. |

|

|

We check with a square - it should be 90˚. |

|

|

Set aside 70 mm from the top edge. |

|

|

In the example, a 16 mm slab is used, therefore, it is necessary to retreat 9 mm from the edge. Why not 8 mm? Because the plate protrudes 1 mm beyond the edge, forming a small side. The middle of the end of the adjacent plate is at a distance of 9 mm. |

|

|

Drilling mark. |

|

|

A similar mark is placed below. |

|

|

Using a drill, we make holes for the fasteners. |

|

|

A special drill replaces three at once. It allows you to make the main hole, the collar and chamfer in one operation. |

|

|

Drilling. |

|

|

We tighten the confirmation with a screwdriver. |

|

|

Having secured the sidewall, we mark the installation locations for the shelves according to the design. |

|

|

Next, using a square, place marks on both sides under the holes for attaching the shelves. |

|

|

Markings along which holes for confirmations will be drilled. |

|

|

The device assembled at the beginning of work is convenient to use for fastening shelves. Using a tape measure, measure 1/2 the thickness of the slab. The thickness of the plate is 16 mm, so we retreat 8 mm from the mark. |

|

|

At this level we install the shelf using quick-release clamps. |

|

|

Here you can clearly see that the mark is in the middle of the end of the workpiece. Everything is ready for drilling. |

|

|

Let's drill. |

|

|

We tighten the confirmations. |

|

|

We install the remaining shelves in the same way. |

|

|

We install the cross member. And we fasten each shelf with confirmations. |

|

|

Having secured the crossbar with a quick-release clamp, we twist it with confirmations at the top and bottom, then secure each shelf. |

|

|

This is how the lower part of the wardrobe is assembled. We clamp the strip from the slab with a clamp and secure it at the end with a confirmat. |

|

|

We drill shallow holes from below for installing furniture legs. |

|

|

We tighten the metal sleeve with external and internal threads. |

|

|

Using a hexagon, tighten (recess) to the required position. |

|

|

We screw the leg with the plastic support into the sleeve. Thanks to this, the furniture can be moved and leveled. |

|

|

Two parts support leg assembly. |

|

|

After assembling the cabinet, a fiberboard sheet is attached to its back side with ordinary nails. |

|

|

We start fixing the fiberboard from the top. By tilting the cabinet from side to side, we achieve a 90˚ angle between the side panel and the top bar. We nail the sides and bottom of the fiberboard sheet. |

|

|

During assembly, no such plastic furniture corners were used. Why? The use of confirmat is much more practical, since it is screwed into the slab a few centimeters and reliably connects the structure, giving it additional rigidity. |

|

|

We close the confirmation hats with a decorative cap. |

Using the same operating sequence, you can assemble a wardrobe of any configuration.

Video:

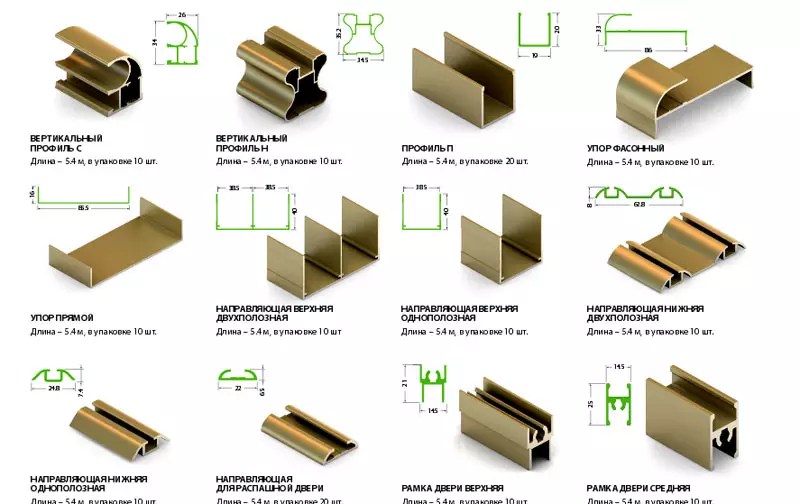

Making doors

The door consists of a frame, metal guides and a roller system. You should order it from a company that professionally deals with such systems. Specialized software will calculate all elements based on given dimensions and issue a complete specification for assembly. Mirrors or slabs from other materials are cut to the size of the doors for mounting in frames.

| Elements for sliding system | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vertical posts/handles for the side parts of the door. |

|

|

Sealing rubber for the mirror. |

|

|

Self-adhesive brush to soften the impact of doors when opening/closing. |

|

|

|

|

|

|

|

|

Brackets for fixing doors in extreme positions. |

The main parts for assembling the doors are made of aluminum. All metal components must be covered with a protective film to protect them from scratches during transportation.

Assembling the sliding system

Let's look at the step-by-step assembly of the door leaf. In our example there will be two mirror doors.

| Door assembly instructions | ||

|

|

The door is located in a horizontal position and provides free access from all sides. | |

|

|

In the upper part of the vertical post, which also serves as the door handle, we drill two mounting holes. | |

|

|

The lower one has a diameter of 6.5 mm. | |

|

|

The top hole is 10 mm. The upper door profile and the roller will be attached through it. | |

|

|

The lower part of the same vertical profile. The upper hole is 10 mm, the lower one is 6.5 mm. The distance from the edge of the first hole is 7 mm, the second is 43 mm. The lower roller will be attached closer to the edge. The second hole is for the screw connecting to the profile. | |

| Profile installation | We fix the rubber seal on top with a profile, carefully inserting it. | |

|

|

We perform the procedure sequentially on all faces. We do not cut off the rubber seal at the corner, but continuously lay it along the entire perimeter. | |

|

|

This screw does not tighten completely. Later the upper rollers will be installed into it. | |

|

|

Install the upper rollers and tighten the screw until it stops. | |

|

|

Rubber seal installed at the bottom of the door. | |

| The screw with the top roller is also tightened | At the top we attach the second pair of rollers. | |

|

|

Install the lower roller. We press the spring on the roller and carefully insert it into the hole, securing it with a screw. | |

|

|

The screw is tightened with a hexagon. | Ready wardrobeWardrobe with first door installed. |

|

|

We assemble and install the second door in the same sequence. | |

Additionally, we install auxiliary elements - a pipe for hangers, etc.

Video:

In the end it should look like this

In the end it should look like this

We invite you to familiarize yourself with the diagrams and drawings. They will help you create your own project.

Video:

Video:

Photo

have recently become one of the most common pieces of furniture. This design provides convenient. Most often, they are not purchased ready-made, but made to order. But if you have the opportunity and the necessary materials, you can make a furniture set yourself. Before you begin, you need to decide on the number/location of shelves and drawers. It is also important to plan the design taking into account the dimensions of the room. In any case, all these points need to be studied before making a wardrobe with your own hands. In this case, the drawings are a kind of starting point, and our review today will help you cope with this rather difficult task with a minimum of errors.

A feature of this type of furniture designs is that they allow you to save usable space in the room. At the same time, sliding doors for a wardrobe can be glass, mirror, rattan, plastic or bamboo.

So, let's look at the main advantages of furniture sets:

- variety of designs: built-in, rectilinear, cabinet and;

- furniture sets allow you to effectively use even a small space. This is an ideal solution for small spaces. At the same time, mirror surfaces allow you to visually increase the space;

- brevity of designs;

- filling wardrobes. Such furniture sets allow you to hide everything unnecessary. They are used not only for clothing, but also for various household items and small appliances;

- models can be built-in, cabinet and with mezzanines;

- the wall of the room, as well as the floor or ceiling can be used as the walls of the cabinet;

- wardrobes are made to order;

- possibility of independent design.

It is worth noting some disadvantages:

- rapid wear of the sliding system;

- high-quality internal filling of the cabinet is required;

- the aluminum profile may be deformed;

- Careful maintenance is required: cleaning all surfaces and guides.

For your information! To prevent the door from coming off the rail, Schlegel for sliding wardrobes is used at the joints and ends. It needs to be glued, which will create shock absorption when the doors are opened suddenly.

Types of wardrobes

Let's look at the main types of wardrobes:

- built-in models that do not have a floor, back wall and ceiling. Such headsets cannot be moved or rearranged. They consist of side walls, shelves and internal partitions. Built-in models are made to order, but you can also purchase separate elements for self-assembly;

- free-standing sliding wardrobes are equipped with doors that move on a rail. This design has a floor, a back wall and a ceiling;

- corner headsets are suitable for small spaces. It is compact in size but very spacious inside. Corner design is suitable for a small rectangular room or square hallway;

- diagonal corner completely occupy the entire corner. Such designs are more spacious and look stylish. Inside you can hide not only a wardrobe, but also bed linen and blankets.

Wardrobe materials

Before you start making a corner cabinet or any other with your own hands, decide on the material.

Tree

For durable sets, you should choose solid wood. This is a prestigious material for furniture. It is worth considering that wood is not the best option for a built-in wardrobe. The humidity level is higher in the niche. For a wooden cabinet, you must carefully select wood that is free from cracks and knots. The frames of the doors are also made of wood. In this case, it is necessary to glue them together.

Wooden sets have the following advantages:

- environmental friendliness of the material. The tree does not contain toxic components;

- increased level of wear resistance;

- aesthetics of products. Wood furniture is distinguished by natural colors and unique patterns;

- naturalness of the material;

- possibility of carrying out restoration work;

- ergonomic use of space;

- variety of styles.

Drywall

One of the popular materials is, which is made from pressed wood chips. To create a dense composition, a thermoactive synthetic resin is used. This material is easy to process.

When working with plywood, it is necessary to take into account the softness of the material. Products may become deformed when twisted. It is recommended to use washers for such connections.

Laminated plywood is also popular. At the same time, plastic reduces the influence of formaldehyde in resins.

Furniture panels

The best material for homemade structures is furniture panels. This material is known for its durability, environmental friendliness and reliability.

It is worth noting the following advantages of using this material:

- does not require significant funds;

- you can bring unusual design ideas to life;

- the product can have different shapes and designs;

- For a furniture set, you can choose functional fittings.

Location of the wardrobe in the room

Before you start creating a wardrobe with your own hands in the hallway or in another room, it is worth considering its location.

If you place the set along a solid wall, then the furniture itself will be perceived as a wall. It would be better if the closet reached the ceiling. Doors can be mirrored, which allows you to visually enlarge the room.

If you place two identical cabinets along the wall and leave a distance between them, you will get an alcove. You can put or in the resulting niche. In the living room, an alcove can be used to create an area with a false fireplace.

A practical solution would be to install the headset along the edges of door and window openings. A mezzanine can be installed above the opening. The cabinet can be recessed into specially created niches. If the size of the room allows, then small sizes can be used.

Depending on the specific design style of the room, it is not necessary to make built-in wardrobes or disguise them. For retro or glam vintage style, bulky furniture will only complement the colorful design.

It is also necessary to choose the right drawer mechanism for the wardrobe. It shouldn't be noisy.

Hallway

Children's

There are many things that need to be placed in a child's room. These include seasonal clothing and shoes, children's toys, board games and sports equipment. In addition, you need to find a place for books, notebooks and bedding.

The sliding wardrobe is a spacious set in which you can place all your things and objects. The doors of this piece of furniture move apart to the sides, which does not take up much space.

Keep in mind that cabinet furniture is selected for children, so the shelves must be at the required height. It is important that there are no sharp corners at the ends of shelves and racks. Each thing must have a specific place, so the child will quickly learn order.

Note! When ordering externally, as a rule, it is not possible to control the consumption of material.

It is important to choose high-quality fittings; the correct adjustment of wardrobe doors depends on this. Doors should not jam or slide. Sliding systems consist of a profile and a sliding support. Roller mechanisms can be axial or bearing-based.

Choosing cabinet filling

The internal content helps decide what the layout will be. You should not place the section for outerwear in the center, as moisture from it can spread to the sides. It is better to place this compartment on the side. Boxes for bed linen are not recommended to be placed directly above the floor.

How to correctly arrange the elements and how to assemble a wardrobe with your own hands can be seen in the video below:

Number and sizes of doors, guides, rollers for wardrobes

When choosing guides for a sliding wardrobe, pay special attention to the material they are made of. The plastic profile has the lowest cost, but it is characterized by low reliability and short service life. The best solution would be to use combined rail guides, in which the supporting surface for the rollers is made of metal.

The steel profile for sliding doors has increased reliability. Rail supports for furniture of famous brands are made from aluminum.

The rollers are made of metal, since plastic is not durable. The roller contains a ball-bearing internal mechanism that allows the door to move freely in the horizontal direction.

Do-it-yourself wardrobe and compartment door assembly

We invite you to familiarize yourself with the process of assembling a sliding wardrobe with your own hands in the table below:

| Photo | Description of work |

| To assemble the wardrobe, you need to apply markings. It is necessary to note the dimensions of the cabinet in width and the location of the vertical rack. The heights at which the shelves will be fixed are noted. |

| Drill holes for dowels. |

| The profile is put on before installation. |

| Install a vertical stand. |

| We mark the mezzanine shelf and install it. |

| The side wall is installed. |

| The shelves are marked and installed. |

| The clothes rail is marked by size and installed. |

| False panels are installed. |

| One panel is fixed at the bottom. |

| The supporting upper part is attached. |

| The bottom guide is secured with a screw. |

| The top guide is attached in the same way. |

| Doors are being installed. |

The process is presented more clearly in this video:

Interesting solutions for sliding wardrobes: photo examples

Don’t forget about the decor of the furniture set. Pilasters can be used as decoration. These elements are made from solid wood or MDF. You can install a furniture cornice on the roof. Interior baguette is used for decoration. You can choose a baguette of different shades. Furniture with photo printing also looks stylish.

Article

Many people are familiar with the eternal problem of lack of space: everything is always out of place, the purchased cabinets are insufficient or do not fit. If you are facing these difficulties, it is time to customize the furniture for your room so that it perfectly suits your personal needs and requirements. Making furniture to order is too expensive, but you can assemble a built-in wardrobe with your own hands, saving a lot of money. In this article we will give you detailed instructions with drawings and assembly diagrams.

The main housing in Russia is small Khrushchev-type apartments, in which every square meter counts. Old Soviet wardrobes are very bulky and roomy - there are useless legs on the bottom, a dust collector on top and empty space, which is usually filled with a mezzanine. Our homemade wardrobe is free of these disadvantages, because it is located either in a niche or the entire height of the room, thus using every centimeter of space.

- The main advantage is spaciousness and compactness. The useful volume of space is 2.5 times greater than that of conventional furniture.

- Sliding doors are why we love sliding wardrobes. They are very practical and do not take up much space.

- Beautiful design - the ability to make doors from a mirror, frosted glass, apply sandblasting, stickers and use any other material to decorate sliding doors.

- Possibility to zone a room using a partition from a closet. We also note that the use of full-length mirrors will have a good effect on the space of the room, making it larger and brighter.

The main disadvantage is the price: if you buy a wardrobe to order or in a store, it will not cost you at all. However, it is quite possible to make a wardrobe with your own hands, the main thing is not to panic and follow the planned work plan.

Cabinet design

Before assembling the wardrobe, you need to finally decide on its drawing and location. Everything is individual here, and there can be no specific advice, just find a good place for the closet. This could be a closet, a niche in the wall, or just a corner in the room.

Before assembling the wardrobe, you need to finally decide on its drawing and location. Everything is individual here, and there can be no specific advice, just find a good place for the closet. This could be a closet, a niche in the wall, or just a corner in the room.

If free space is not limited, then choose the size of the cabinet according to the golden ratio rule, according to which the ratio of height and length should be 1.62.

Thus, if your ceiling is 2.5 m high, then it would be optimal to choose a cabinet length of 154 cm (250/1.62=154.3). The depth of standard furniture parts is usually 60 cm; there is no need to make it more, otherwise it will be inconvenient to get distant things from the upper shelves. Also note that all internal parts must be at least 10 cm narrower due to the width of the doors.

When you decide on the installation location, you need to draw up drawings. Make a detailed diagram of the cabinet and all shelves with dimensions on paper or on the computer (choose the Basic Cabinet or Excel program). Specialized programs will be able to give you with one button the number and dimensions of the required parts for cutting, which is very convenient.

When modeling interior shelves, you can’t do without your significant other, otherwise you’ll have to redo everything later. Modeling is one of the most important stages, which should be devoted to a separate topic, so now we will only briefly present our sliding wardrobe project with dimensions.

Drawing of a built-in wardrobe in a niche

Drawing of a built-in wardrobe in a niche This wardrobe diagram is designed to be created in a closet with a beam at the top. Therefore, mirrored doors will not go all the way to the ceiling.

Filling

When creating the shelves, we will use ordinary light-colored chipboard boards. To fasten them we will use metal corners and self-tapping screws.

After calculating the materials for the cabinet, we bought the necessary parts and ordered cutting and edge processing on site:

- 3 parts 150x60 cm (horizontal);

- 2 parts 200x60 cm (vertical for walls);

- 1 vertical partition 135x60 cm;

- 3 vertical partitions for shelf compartments 32.5x60 cm;

- 1 horizontal sheet 150x30 cm for the shelf behind the beam;

- 3 partitions for a shelf behind a beam 30x40 cm.

The main thing here is not to make mistakes in the calculations, so before ordering parts, carefully study the drawing and calculate all the gaps.

Build process

Now about how to assemble a wardrobe with your own hands.

- First, we laid the 150x60 piece on the floor and attached two side boards to it. By the way, if you have a plinth, it is better to remove it, otherwise you will have to cut the walls at an angle. The fastening took place using dowels to the wall and metal corners to the bottom board using self-tapping screws. Some people use plastic furniture corners for shelves, but they are not so reliable: a child will stand on the shelf and it will collapse.

- Then we assembled the internal shelves separately: we connected 2 horizontal boards 150x60 (which will be above the bar) with a vertical piece 135x60 and three small transverse compartments 32.5x60.

- The finished compartments were secured to the cabinet in the same way, using corners and screws. If you have access to the side walls, then you can use a Euroscrew for fastening - a popular furniture fastener that is used for tables and shelves.

- Now all that remains is to make the upper shelves; we also prepared them separately from the outside. We attached three vertical partitions 30x40 every 50 centimeters to a horizontal board 150x30.

Note! If you are making a cabinet with a full-length top lid, you may have problems with its fastening. In this case, leave the required height so that you can climb up with a hexagon from above or attach the cover to the corners from the inside.

As a result, we got 2 large compartments for hangers, where all outerwear, shirts, dresses, etc. will fit. Then there is 1 large shelf on one side, and the other side is divided into 3 small compartments. Above there is one wide shelf, which is divided into 3 narrow compartments against the wall. And at the very top there is a shelf for unnecessary things. Everything is shown in the photo below.

Door installation

Now about the most difficult part - the wardrobe. In order not to make a mistake with the size, it is better to buy them after assembling the frame. You can watch a video about assembling a mirror door from profiles:

It is not recommended to make the width of sliding doors more than 1 meter, so if the length of the cabinet is 154 cm, divide it in half: each door, roughly speaking, is 77 cm + an overlap of 2-4 cm so that there is no gap.

Calculation of wardrobe doors

Calculation of wardrobe doors Regarding the height of the doors, it is important to consider the height of the lining and wheels.

For example:

- 250 centimeters - ceiling height (or opening);

- 1.6 cm - thickness of laminated chipboard linings on top and bottom;

- The gap at the top and bottom is 1.5 cm for the wheels;

Total: 250-1.6-1.6-1.5-1.5 = 243.8 cm - the height of our doors. You should have side handle profiles of this height. The clearance figures may vary, it all depends on the profiles used, so read the instructions from their manufacturer.

Sliding door design

Sliding door design - Since we are attaching the doors to the widened doorway of the pantry, we need to make a laminated chipboard gasket around the perimeter.

- Now let's cut the required length of the door guides. They should be equal to the width of the cabinet inside and fit freely between the walls. They must be secured strictly level and parallel to each other. First, we attach the upper rail to self-tapping screws with a press washer, then the lower one. Be sure to insert the stoppers into the bottom track when the doors are closed.

- When the guides are level, you can insert the door. The far door is first inserted into the top track and then lifted to fit into the bottom. The front door is inserted in the same way - first insert the top, then the bottom.

- To adjust the doors, tighten the special bolt at the bottom with a hex key. If you tighten the bolt, the door will rise, if you unscrew it, it will lower. If the doors are parallel and adjusted, then everything will run like clockwork, but if they are installed incorrectly, then sometimes the upper rollers can pop out.

- At this point, the installation of the wardrobe is completed; now you can hang hooks, secure the hanging rod and, if necessary, add drawers.

To finally figure out how to assemble a wardrobe with your own hands, the video lesson will tell you all the details during installation:

Conclusion

By doing all the work yourself, you will save 2-3 times more money than ordering a similar cabinet in a store, and you will also make it several times faster if desired. The main thing is to be careful and calculate every action before starting work. As they say, measure twice, cut once.

Ecology of consumption. Life hack: Building a built-in wardrobe with your own hands is quite a troublesome task. Without specific carpentry skills...

Building a built-in wardrobe with your own hands is quite a troublesome task. Without certain carpentry skills, working with wood and getting an excellent result in the end is quite difficult. But everything can be learned with experience. And if you start equipping your house with built-in wardrobes in every niche, starting with an inconspicuous cabinet on the balcony, then in the kitchen, then finding a huge niche in the living room, the cabinets will gradually give in.

It is recommended to build such cabinets for those who really have little space and a lot of things in their house, who want to save money on buying a ready-made cabinet, or who have beautiful unnecessary openings and niches in the walls created just for the cabinet.

A cabinet attached to the wall is good because it is stable, does not wobble or rattle from a person passing by. And most importantly, the absence of side and rear panels allows, with the same external dimensions of the cabinet, to gain significant useful internal volume: an entire additional large drawer (25 liters) or two extra hanging fur coats - isn’t this good luck for the owner of a dozen fur coats and a small room?

Having understood the specifics of design and installation, you can get down to business.

Design

When designing the interior space, shelves and hangers can be modeled to suit your needs. It is necessary to choose such an interval between the shelves that there is practically no empty space left.

It is better to mount the crossbar for hangers closer to the ceiling so as not to waste space.

Compartments for linen and clothes – 30-40 cm high.

If you plan to eventually build a TV or stereo into the closet, secure the space for it in advance.

After the measurements, a drawing is drawn up; you can even try to draw the entire room and the designed cabinet on a computer using special programs. Then the possibility of detailed modeling and the sketch becomes clearer.

The original walls and ceiling, or rather the degree of their curvature, can bring great help or, on the contrary, trouble into the construction of the cabinet. If the ceiling and walls are perfectly aligned and all angles between them are 90 degrees, the cabinet is incredibly lucky. Aligning the parts will be easy.

Another option is to align the planes by level and plumb (more correct and accurate), but then the walls of the built-in closet may deviate significantly from the planes of the walls (if they are very crooked) and this will be noticeable. In general, the choice of what is best to align the cabinet with is made empirically. But all parts must be without gaps, adjacent to the floor, walls and ceiling.

It is better to use the same fittings for the cabinet - handles of the same shape and color, albeit of different sizes, screwed at the same distance from the edges of the drawers and doors.

There are times when it is difficult to cut one large piece (such as a long side wall panel) from one piece of wood. Therefore, you can make long side walls through the borders, that is, attach several small boards with an overlap. Then take two strips of equal length, touch one to the floor, the other to the ceiling, strictly above each other and screw it in with screws. Then, in the remaining distance between them (dimensions are added for overlap), a third sheet is cut out, touched to the wall and screwed to the borders with an overlap. This will create a neat wall with borders. On the front side, these borders can be beautifully covered with doors (if they are made at the level of the overlaps).

It is better to place the cabinet on a hard surface (it is better to remove overhead floors or layers of floor “pie” with insulation). Think about whether it’s worth stripping the base of the floor down to the concrete. Hard surfaces such as parquet or linoleum will support an average cabinet; laminate flooring will most likely have to be removed, as a heavy cabinet can cause waves on the surface.

If you plan to make glass parts in the cabinet, you should think in advance whether to insert them into the doors or make them completely glass. The second option will be easier. Instead of glass, you can use a mirror, which is protected from scratches with a special coating, such as waterproof varnish.

When planning and building a cabinet, do not forget about the characteristics of the material; an important detail, for example, is the direction of the fibers in the wood board. Depending on this, you can cut the material correctly or incorrectly. Wood along the grain is much stronger than across it. In plywood, the layers of fibers are directed crosswise, so the strength qualities at any point are approximately the same. In furniture panels, it is important to ensure that the fibers are directed from one planned attachment point to another. If the fibers on the material are not clearly visible, it is considered that they run along the long side of the sheet, and the part must be cut out, taking into account the attachment points, along it.

During installation, gaps of a few millimeters must be left to allow large wooden parts to expand due to fluctuations in air humidity. These gaps can be filled with small wood chips to prevent dust from passing through. If possible, it is better not to make too long parts (over 80 cm with a width of 60 cm) that will not be supported by anything in the middle (for example, horizontal shelves), since the “fluidity” of the wood will manifest itself in a few years, and the shelf may sag.

Construction using the example of a wardrobe

Sliding wardrobes differ from ordinary built-in ones only in the design of the doors, so the principles of their installation in a wall niche are the same.

First, an internal supporting frame is made; thin panels made of various materials are fixed to the frame: ogralite, textolite, fiberglass. Load-bearing vertical panels (if they are used and not walls) are firmly attached to the wall. Gaps in the inner corners are closed with precisely fitted square or profiled slats.

You can use elements of the room as the side walls of the cabinet, as well as the floor. But if the walls are too crooked, a better alternative would be to install a separately knocked-together cabinet into the wall. This is especially important for a wardrobe, since the curvature of the planes will cause the moving door mechanisms – rollers and rails with doors – to suffer greatly or even not work.

If you install a wardrobe in a niche with uneven side walls and floor, the cabinet's construction mechanisms will quickly wear out. Therefore, before installation, all surfaces are leveled using false panels and beams. If the deviation of the walls from the vertical is insignificant, then the walls are not leveled, but the door is tilted using adjusting screws.

The opening of the wardrobe should be larger and higher than the height of the sliding panels - about 5 cm. The width of the opening of the wardrobe should allow for overlap (when one door overlaps another), it should be at least 2 cm. If there are 4 in the wardrobe sash, the overlap will be 4 cm.

Usually a wardrobe has its own floor inside the wardrobe. This is done not only from a decorative point of view, but mainly to level the floor under the rails - the lower door guide.

For linoleum and laminate, if you don’t want to disassemble it, be sure to cut a strip a few cm wide around the perimeter of the future cabinet under the rails. Sliding wardrobes are not installed on “floating floors”. For carpet, an additional floor is made of chipboard or a backing under the lower door guide so that the door does not press into the pile.

The upper guide is attached to the ceiling. The bottom rail is installed on the floor with an offset of 30 mm relative to the top rail into the depth of the cabinet. First, the doors are checked to see how they move in the grooves, and only then the guides are screwed “tightly” to the floor.

A horizontal clothes hanger is placed in the closet at a distance of at least 6 cm from the mezzanine shelf. There should be at least 150 cm from the same stick to the shelf with shoes (so that hanging clothes do not touch the shoes). The hanger should be at least 21 cm away from the back wall.

When in the extreme open position, the door should not interfere with the drawers being pulled out. It is convenient to divide the interior space of the cabinet into as many sections as there are doors in the cabinet - into two if there are two doors, into three sections if there are three doors.

The installation of doors in a wardrobe is carried out as a last resort - after installing all partitions, walls and floors and completing work on the internal structure. First, install the inner door (starting with the insertion of the upper rollers). Then the right door is installed. Before installing the doors, self-adhesive shock absorbers are installed on the side walls of the furniture frame, which will soften the impact of the door on the walls of the wardrobe. published